- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

What is as small as a molecule, and as big as a shipping container? The answer is Alphabet Energy’s thermoelectric generation technology, and it could make a significant contribution to electricity generation at remote oil and gas sites.

Thermoelectric generators, once the purview of large, well-funded organizations like NASA, due to their high manufacturing costs and reliance on rare materials, are starting to become a commercially viable option, thanks to Alphabet, which was founded in 2009 by materials scientist, Dr. Matthew L. Scullin.

In 2014, Alphabet made headlines when it began selling the E1 generator -an industrial-scale thermoelectric generator that uses nanotechnology to efficiently and cost-effectively produce electricity from waste heat. The E1 is currently at work at a site on the Eagle Ford shale, in South Texas, and will be up and running at the Utica shale, in the Northeastern US as early as next month (April 2016).

Trinity Power spoke with Mothusi Pahl, Alphabet’s VP of Marketing, to talk about the technology behind the E1, and its applications in the oil and gas industry.

While thermoelectric generation has existed for some time, Pahl explains that three factors have prevented it from being commercially viable in the past: it has required rare, difficult to obtain materials; its manufacturing process has been very complex; and it has been manufactured in small volumes, preventing it from reaching economies of scale.

So what’s different about Alphabet’s technology? “All of the work at Lawrence Berkley National Labs, where Alphabet originated out of, was around novel materials like silicon nanowires,” explains Pahl, “where you can harness the thermoelectric effect, but do it at much lower cost.” It is because of the silicon nanowires, and a material called tetrahedrite, both of which can be sourced domestically and relatively cheaply, that Alphabet is able to produce its thermoelectric technology, including the E1, at a reasonable cost.

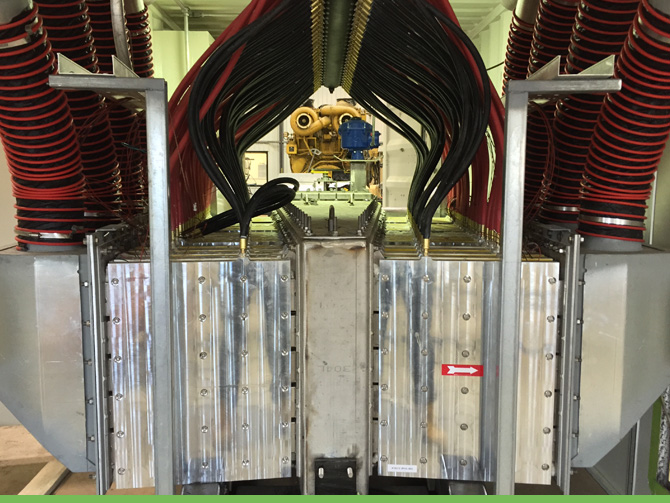

On a larger scale, this means that the E1 is able to reduce energy costs for remote sites, such as those on the Eagle Ford and Utica Shales. “The applications that we’re focused on are scenarios where we find sites that have a lot of mechanical power on site,” explains Pahl, “typically in the form of gathering line compression engines and pumping stations, or compressor stations.” The generator attaches to a source of waste heat -typically diesel or gas exhaust from these engines- which is then condensed and run across a temperature gradient to generate electricity: up to 25 kWe from a 1000 kW engine.

This exact scenario is the case at Eagle Ford, where Alphabet is running some of its equipment. “It’s a remote location, no power lines in the area, they’re running five caterpillar 3516s on site, and they wanted a reliable source of electricity,” explains Pahl, adding that they want this reliable source of electricity to power things like SCADA, controls, lighting, security, on-site computer systems, and instrument air -a kind of filtered compressed air used for pneumatic instruments. With an E1 hooked up to one of the 1500kW CAT engines, Alphabet says they have taken the first step in proving that this will be possible.

Most recently, Alphabet has begun looking at applications that go beyond engine exhaust. “We started exclusively looking at these engines, and the exhaust streams coming off these engines,” says Pahl. “But we’ve had a number of customers who’ve asked us…’Can I use the same technology and route the high exhaust gas coming off of my flare stack through your system and generate electricity off of those flares?’”

According to Pahl, Alphabet will be doing just that, starting as early as next month, at the Utica shale. Says Pahl, “That’s probably the [application] that’s of the greatest interest, particularly in BC and Alberta, simply because of the amount of flaring.”

In cases like Eagle Ford, and other remote sites, Pahl says, thermoelectric represents an alternative to solutions like solar, which not only requires a fair amount of sunlight to work, but according to Pahl, also runs the risk of theft, and 5kWe to 25kWe diesel generators, which can be costly to maintain. In fact, according to Alphabet’s website, the E1 requires no maintenance -a claim Pahl echoes: “We don’t have as many pieces of moving equipment -we don’t have a combustion process that we’re worried about. Which at the end of the day means there are fewer things that could break,” he says, “which means, you end up saving your customer a good chunk of money.”

We did some math, and the numbers are intriguing. If the E1 generated its maximum output of 25kWe, 24/7, the annual fuel savings would be about 69,636 liters. At the current selling price of diesel, that works out to about $55,709 saved annually. These numbers don’t account for times when the E1 isn’t producing its maximum output, but even so, they are significant.

In fact, according to Pahl, the E1 has a payback period of less than 2 years, even with variables like run-time taken into account. To help customers start saving immediately, Pahl explains that Alphabet also offers a leasing option. “Right off the bat we’re able to show them fairly significant cost savings, in terms of equipment they didn’t have to buy.”

Given the economic realities facing the industry today, technologies like the E1, which offers a way to maximize a site’s efficiency, are getting much more attention than they did when things were booming. “Lower commodities prices have forced the community to pay a lot more attention to their bottom line,” says Pahl. “Today, the priority is not on expansion, it’s on how do you make your operation more profitable.”

And right now, helping operations to be more profitable is something Alphabet is doing its best to achieve. As Pahl enthuses, “It’s a really cool space to be in a place where we can offer a value proposition that these end users can’t get anywhere else.”

Related Articles

Subscribe for Access to Exclusive Content

Get insider updates, industry news, special equipment offers, and expert tips—directly to your inbox.

"*" indicates required fields